In recent months, natural disasters have once again underscored the fragility of global supply chains, with hurricanes and seismic events creating ripples across industries. In Florida, Hurricane Milton made landfall after fluctuating between Categories 4 and 5, prompting mass evacuations along the Gulf Coast and threatening vital infrastructure. The state was still reeling when Hurricane Helene struck, bringing physical damage and a wave of misinformation and safety concerns. Meanwhile, across the Pacific, major earthquakes in Japan and a series of powerful typhoons in Southeast Asia, such as Typhoon Yagi, have spotlighted the vulnerabilities of manufacturing and production hubs.

These events are a stark reminder that the global supply chain, especially in critical sectors like semiconductors, is highly susceptible to disruptions caused by natural disasters. As companies scramble to recover from these shocks, the lessons learned from each incident can help build a more resilient, future-proof supply chain. This article delves into how these natural disasters have affected the supply chain, focusing on the semiconductor industry. It explores strategies for mitigating such risks in the future.

Understanding the Supply Chain’s Vulnerability to Natural Disasters

The semiconductor industry is particularly sensitive to disruptions due to its reliance on specialized production processes and rare materials. A single event can trigger a chain reaction, causing delays in manufacturing and shipment that ripple through the industry. For example, the pandemic-induced global semiconductor shortage highlighted how even minor disruptions could lead to major production delays and bottlenecks in sectors ranging from automotive to consumer electronics. While the pandemic was an unprecedented challenge, the rise in extreme weather events has added a new layer of uncertainty to the global supply chain.

The year 2024 has been marked by several significant natural disasters that have disrupted critical manufacturing and logistics hubs. Events like the earthquake in Japan, flooding in South Korea, Typhoon Yagi in Vietnam and Thailand, and wildfires in Russia have had far-reaching consequences. These incidents threaten the physical infrastructure of production facilities, delay transportation, affect raw material supply, and increase costs for companies trying to navigate the aftermath.

Critical Natural Disasters of 2024: A Closer Look

- Earthquake in Japan (January 2 – January 16, 2024): Japan is a pivotal hub for semiconductor manufacturing, known for its precision equipment and advanced materials. The earthquake in early 2024 caused significant disruptions in production lines, affecting the output of critical materials needed for semiconductor manufacturing. Facilities in regions like Kumamoto, where many semiconductor fabs are located, experienced temporary shutdowns. Although damage to the fabrication sites was limited, the delays in production impacted global shipment schedules, leading to bottlenecks that resonated across supply chains worldwide.

- Flooding in South Korea (July 22 – August 5, 2024): South Korea is home to major semiconductor manufacturers like Samsung and SK Hynix, which are integral to the global supply of memory chips. The July 2024 floods submerged key production facilities and disrupted logistics networks, causing delays in shipments and a temporary slowdown in memory chip production. Given that South Korea accounts for nearly 60% of global memory chip production, even a short-term disruption can affect prices and availability, making this a critical event for the industry.

- Typhoon Yagi in Vietnam and Thailand (September 11 – September 26, 2024): Vietnam and Thailand are increasingly essential hubs for electronics assembly. Typhoon Yagi caused substantial damage to production facilities and disrupted port operations in both countries, delaying shipments of assembled electronics and components. This, in turn, affected the delivery of products to customers in Europe and North America, underscoring the ripple effects of localized disasters on global supply chains.

- Hurricane John in Mexico (September 30 – October 14, 2024): Mexico plays a crucial role in manufacturing automotive and electronic components as a vital link between North American markets and global supply chains. Hurricane John led to temporary closures of crucial production facilities and damaged logistics infrastructure, further straining the supply of automotive and electronic components. The disruptions were felt most acutely in the automotive sector, which relies on just-in-time manufacturing and had already grappled with semiconductor shortages.

- Flooding in India and Bangladesh (August 27 – September 17, 2024): India and Bangladesh are emerging as significant players in global electronics manufacturing. The floods in these regions disrupted local production and delayed the delivery of raw materials to other manufacturing hubs. These disruptions have a cascading effect, impacting companies that depend on a stable flow of components and raw materials, particularly for assembly operations in other parts of Asia.

- Wildfires in the Russian Federation (July 2 – July 16, 2024): Russia is a key supplier of rare earth metals and other materials used in semiconductor production. The July wildfires affected the extraction and transportation of these critical resources. While the direct impact on semiconductor production was limited, the disruption of raw material supply highlighted the vulnerabilities in the industry’s sourcing strategies.

- Dual hurricanes Milton and Helene on the Florida Coasts (September 23 – Ongoing): The destruction of infrastructure, including ports, roads, and power grids, will inevitably disrupt the flow of goods and materials. This will lead to delays in production, shortages of critical components, and increased costs. The semiconductor industry, which relies heavily on a complex global supply chain, will be particularly vulnerable. Damage to manufacturing facilities and disruptions in the supply of raw materials could result in shortages of semiconductors, essential for a wide range of electronic devices.

The Ripple Effects of Natural Disasters on the Semiconductor Industry

Natural disasters like those experienced in 2024 exposed the fragility of the semiconductor industry’s supply chain. Unlike other sectors, semiconductor production requires precise conditions and specialized equipment. Even a short-term disruption can result in significant delays and economic losses. The following are some of the key ways natural disasters impact the semiconductor supply chain:

- Disruption of Production Facilities

Semiconductor manufacturing relies on highly specialized fabs that produce silicon wafers, the foundation of microchips. Natural disasters such as earthquakes, floods, and hurricanes can damage these facilities, leading to production halts. For example, the earthquake in Japan caused temporary shutdowns of key fabs, delaying production schedules and impacting global shipments. Each delay at a fab can lead to shortages of microchips, which are critical for products ranging from smartphones to vehicles.

The impact of natural disasters on production facilities isn’t limited to direct damage. Power outages, transportation disruptions, and infrastructure damage can delay production’s restart, exacerbating the initial impact. In Japan, power outages caused by the earthquake affected production lines even after the physical damage was contained.

- Disruption of Raw Material Supply

Natural disasters can also impact the supply of raw materials necessary for semiconductor production. A recent example is the flooding caused by Hurricane Helene in North Carolina, which temporarily shut down the world’s purest quartz mines in Spruce Pine, a key ingredient in semiconductor manufacturing. Although existing inventories mitigated the impact of this particular event, it highlighted the supply chain’s vulnerability to disruptions in raw material sources.

The wildfires in Russia this year similarly disrupted the extraction of rare earth metals. While these materials represent a small fraction of the total semiconductor production process, any disruption can cause a ripple effect that delays manufacturing timelines, increases costs, and affects downstream industries.

- Logistics and Transportation Challenges

Natural disasters can damage infrastructure such as roads, ports, and airports, making transporting materials and finished goods difficult. For instance, Typhoon Yagi in Vietnam and Thailand caused significant shipping delays, affecting the global supply of assembled electronics. The disruption of port operations and damaged transportation routes led to extended delivery times, impacting manufacturers dependent on just-in-time inventory strategies.

In Mexico, Hurricane John affected the transport routes for electronic components, leading to delays in deliveries to automotive manufacturers in the U.S. and Canada. These delays not only slowed down production but also increased logistics costs as companies were forced to find alternative shipping routes or rely on more expensive air freight to meet deadlines.

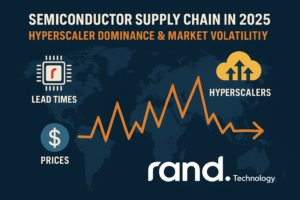

- Increased Costs and Market Volatility

When production and logistics are disrupted, companies face increased costs in several areas. Repairing damaged facilities, finding alternative suppliers, and paying higher transportation fees can significantly increase operational expenses. For the semiconductor industry, these costs often get passed on to end-users, leading to price increases for consumer electronics, automotive components, and other products reliant on chips.

For example, the floods in South Korea caused temporary price spikes for memory chips as production slowed. This volatility affects not only manufacturers but also industries that rely on stable chip supplies, such as automotive, consumer electronics, and telecommunications. Such price fluctuations can impact companies’ bottom lines and lead to financial losses if they are unable to absorb or pass on the increased costs.

Strategies to Mitigate the Impact of Natural Disasters

The semiconductor industry and its stakeholders must take proactive measures to mitigate the risks associated with natural disasters. Given the unpredictable nature of these events, building resilience in the supply chain is essential. Here are three strategies that companies can adopt to reduce the impact of natural disasters:

- Diversification of Supply Chains

One of the most effective ways to reduce the impact of natural disasters is to diversify supply chains. This involves sourcing materials from multiple regions, using a network of suppliers, and maintaining relationships with alternative manufacturers. For example, companies heavily reliant on raw materials from a single source, such as quartz from North Carolina, should explore partnerships with suppliers in India or China. While these alternatives may not match the purity standards of Spruce Pine quartz, having diverse sources can reduce the risk of supply chain disruptions.

Diversification also applies to semiconductor production. By investing in fabs across different geographic regions, companies can reduce the risk of supply chain disruptions caused by localized events. The global semiconductor shortage of the past few years has prompted many chipmakers to explore expanding production capacity outside traditional hubs, including new facilities in the U.S., Europe, and Southeast Asia.

- Investment in Domestic Manufacturing

Governments and companies are increasingly recognizing the importance of building domestic manufacturing capabilities. The U.S. CHIPS Act and similar initiatives in the European Union and Asia aim to enhance local semiconductor production capacity, reducing reliance on a few key hubs. This investment can help create a more resilient supply chain that is better prepared to withstand disruptions from natural disasters.

Domestic manufacturing ensures a more stable supply of semiconductors and supports quicker recovery when a natural disaster strikes. Companies can rely on domestic production to fill the gaps and maintain supply continuity if a disaster affects a particular region. This approach is particularly crucial for industries like automotive and defense, where chip shortages can cause production shutdowns.

- Leveraging Advanced Technology for Resilience

Data-driven insights and advanced technology, such as AI, can help companies identify vulnerabilities in their supply chains. Predictive analytics and real-time monitoring tools can provide early warnings about potential disruptions, allowing companies to adapt quickly. Advanced software can optimize supply chain operations, schedule shipments more efficiently, and find alternate suppliers or routes when disruptions occur.

Building Resilience in an Uncertain World

At Rand Technology, we understand the critical role of resilient supply chains in today’s interconnected world. The natural disasters of 2024—be they hurricanes in Florida or earthquakes in Asia—have made it clear that proactive preparation is the key to maintaining continuity in the face of disruption. For industries like semiconductors, where precision and stability are paramount, these events serve as a reminder that the best strategies are those that account for uncertainty.

Rand Technology is committed to helping businesses navigate these challenges. Through our global partnerships, diversified supply chain solutions, and commitment to quality, we offer our clients the security of knowing that even in times of crisis, their supply chain is in good hands. By investing in diversified sourcing, leveraging advanced analytics, and strengthening regional manufacturing capabilities, we work to build a future where supply chains can withstand the unexpected.

Natural disasters may be inevitable, but their impact doesn’t have to be. With a trusted partner like Rand Technology, businesses can turn uncertainty into an opportunity for resilience and growth. As the world faces more frequent and intense natural events, it’s time to prepare for the future—because a robust supply chain is not just a competitive advantage; it’s a necessity.