In the rapidly evolving landscape of technology, partnering with a reliable components distributor is crucial for businesses that rely on integrated circuits and semiconductors. The complexity of supply chains, the fast pace of innovation, and the high stakes of maintaining quality and compliance mean that choosing the right distributor can significantly impact a company’s success. Rand Technology, the global leader in Supply Chain Management, understands these challenges and provides comprehensive solutions that underscore the value of working with a specialized distributor. Here are five compelling reasons to consider partnering with a components distributor.

1. Access to a Broad and Diverse Inventory

Expansive Product Range

One of the primary advantages of partnering with a components distributor like Rand Technology is the access it offers to an extensive and diverse inventory. Distributors maintain relationships with a wide array of manufacturers, enabling them to provide a vast selection of components. This breadth of inventory ensures that businesses can find the specific parts they need, whether standard or rare, current or obsolete. For instance, during the global chip shortage, many manufacturers struggled to source critical components. However, those partnered with robust distributors could still access necessary parts, minimizing disruptions.

Global Sourcing Network

Distributors leverage a global network to source components, providing customers access to products from different regions and manufacturers. This global reach ensures that distributors can still procure the necessary components even during supply chain disruptions, such as those caused by geopolitical tensions or natural disasters. For example, when the COVID-19 pandemic disrupted supply chains worldwide, distributors’ global networks enabled them to source components from less affected regions, maintaining supply continuity for their clients.

Tailored Solutions

Component distributors offer tailored solutions to meet their clients’ unique needs. They provide flexible and customized services, whether it’s a custom inventory program, specific packaging requirements, or specialized testing. This level of customization helps businesses streamline their operations and focus on their core competencies. For instance, a company developing a new product might require components packaged in a specific way to fit their automated assembly process. A distributor can meet this need, ensuring the components are ready for seamless integration into the production line.

2. Enhanced Supply Chain Efficiency

Inventory Management

Effective inventory management is crucial for maintaining a smooth supply chain. Distributors employ advanced inventory management systems that provide real-time visibility into stock levels, lead times, and demand forecasts. This transparency helps businesses reduce excess inventory, minimize stockouts, and optimize their procurement strategies. For example, Rand Technology uses sophisticated software to track component availability and predict demand trends, helping its clients avoid costly production delays and excess stock.

Just-in-Time Delivery

Many component distributors offer just-in-time (JIT) delivery services, ensuring that components arrive precisely when needed in the production process. This approach reduces the need for extensive on-site inventories, freeing up valuable space and resources. Distributors help businesses maintain lean operations and reduce carrying costs by aligning deliveries with production schedules. For instance, an electronics manufacturer might schedule deliveries of integrated circuits to coincide with their production cycles, minimizing storage requirements and reducing waste.

Logistics Expertise

Distributors possess extensive logistics expertise, managing the complexities of global shipping, customs clearance, and regulatory compliance. Their experience handling international shipments ensures that components are delivered efficiently and without delays. Rand leverages its logistical capabilities to provide seamless delivery solutions to its clients. For example, during peak shipping seasons, these distributors can navigate congested shipping lanes and customs bottlenecks to ensure the timely delivery of components.

3. Quality Assurance and Compliance

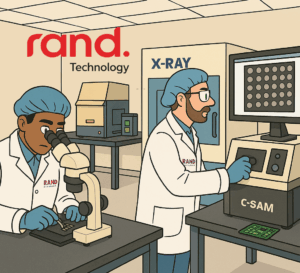

Stringent Quality Control

Quality is paramount in the electronics industry, where faulty components can lead to product failures and significant financial losses. Distributors implement rigorous quality control processes, including thorough inspections, testing, and certifications, to ensure that all components meet the highest standards. Rand Technology employs advanced testing methodologies to verify the authenticity and performance of each part. Multiple case studies have shown that companies working with distributors emphasizing quality control experience fewer product recalls and higher customer satisfaction.

Compliance with Industry Standards

Distributors stay abreast of industry standards and regulations, ensuring that the components they supply comply with relevant certifications such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). This compliance guarantees that the components are safe, environmentally friendly, and legally permissible for use in various applications. For instance, a medical device manufacturer must use components that meet stringent safety and environmental standards. By sourcing from compliant distributors, they ensure their products meet regulatory requirements.

Counterfeit Prevention

The risk of counterfeit components is a significant concern in the electronics industry. To mitigate this risk, distributors implement robust anti-counterfeiting measures, including supplier audits, traceability, and authentication techniques. By sourcing components from authorized and reputable manufacturers, distributors protect their clients from the dangers of counterfeit products. For example, Rand Technology employs advanced traceability systems to track each component from the manufacturer to the end user, ensuring authenticity and reducing the risk of counterfeit infiltration.

4. Cost Savings and Financial Benefits

Volume Discounts and Competitive Pricing

Distributors purchase components in bulk, allowing them to negotiate favorable pricing with manufacturers. These cost savings are passed on to customers in the form of competitive pricing and volume discounts. Businesses can leverage these financial benefits to reduce procurement costs and improve their bottom line. For instance, a large electronics firm might receive significant discounts by ordering high volumes of semiconductors through their distributor, resulting in substantial cost savings.

Flexible Payment Terms

Many distributors offer flexible payment terms, providing businesses the financial flexibility to manage their cash flow effectively. Options such as extended payment terms, credit lines, and financing solutions help companies navigate the financial challenges associated with large-scale component purchases. For example, a startup developing a new tech product might benefit from extended payment terms, allowing them to invest in R&D while managing their cash flow efficiently.

Total Cost of Ownership (TCO) Reduction

Working with a distributor can also reduce the total cost of ownership (TCO). Distributors handle various aspects of the procurement process, including sourcing, logistics, and quality assurance, which can reduce the indirect costs of these activities. By streamlining these processes, businesses can achieve greater cost efficiencies and operational savings. For instance, an automotive manufacturer might reduce its TCO by outsourcing component procurement and logistics to a distributor, allowing them to focus on core manufacturing processes.

5. Technical Support and Expertise

Engineering Support

Component distributors provide valuable technical support and expertise to their clients. Their engineers and technical specialists offer guidance on component selection, compatibility, and integration. This support is particularly beneficial for businesses developing complex electronic systems, as it ensures that the chosen components meet the technical requirements and performance standards. For example, a company developing a new smart device might rely on its distributor’s engineering team to recommend the best components for optimal performance and reliability.

Design Services

Some distributors, such as Rand Technology, offer design services to assist clients in developing custom solutions. These services include schematic design, PCB layout, and prototyping. By collaborating with distributors on design projects, businesses can accelerate their product development timelines and bring innovative products to market more quickly. For instance, a startup developing a wearable device might work with their distributor’s design team to create a custom PCB layout, ensuring the final product meets all design and performance specifications.

Training and Education

Distributors also play a crucial role in educating clients about the latest industry trends, technologies, and best practices. They offer training sessions, webinars, and technical workshops to keep clients updated. This ongoing education helps businesses stay competitive and leverage the latest advancements in the electronics industry. For example, Rand Technology frequently hosts webinars on emerging technologies and supply chain strategies, providing valuable insights to their clients.

Conclusion

Partnering with a components distributor offers numerous advantages for businesses in the electronics industry. The benefits are substantial, from access to a broad and diverse inventory to enhanced supply chain efficiency, stringent quality assurance, cost savings, and technical support. Distributors like Rand Technology provide the expertise and resources needed to navigate the complexities of the electronics supply chain successfully.

In an era where technological innovation drives market competitiveness, having a reliable components distributor is more critical than ever. By leveraging the capabilities of a trusted distributor, businesses can streamline their operations, reduce costs, and focus on what they do best—innovating and delivering high-quality products to their customers. Whether you are a small startup or a large enterprise, the right distribution partner can significantly impact your journey toward success in the electronics industry.

Choosing to work with a components distributor is not just about sourcing parts; it’s about forming a strategic partnership that drives efficiency, quality, and innovation. Rand Technology is not just a supplier; they are integral partners in your business success, providing the expertise, resources, and support needed to thrive in a competitive market.