When you’re responsible for keeping high-reliability products moving—aircraft, medical devices, industrial control systems, defense platforms—the most dangerous component is the one you think you can trust. Over the last decade, the global electronics supply chain has become increasingly complex, time-pressed, and more vulnerable to risk. That is precisely why aerospace-grade quality standards exist for distributors and independent sources: to make trust verifiable.

At Rand Technology, we don’t just hold these certifications—we continually prove them through annual surveillance audits. Most recently, our Rand Technology EMEA B.V. operation successfully passed its AS9120 & AS6081 audits with an expanded scope that covers Sales, Purchasing, Receiving, Inspection, Testing, and Distribution. This wasn’t a new certification; it was the latest confirmation that our systems and people are consistently performing to the highest aerospace and anti-counterfeit standards.

Two of the most important standards in this space are AS9120 and AS6081. If you buy, qualify, or integrate electronic components, understanding what these standards mean—and how a certified partner uses them—directly affects your risk, your costs, and your schedule.

This blog demystifies both standards in plain language, explains how they work together, and outlines the changes they bring to you when you select a certified partner like Rand Technology.

Quick definitions

- AS9120

AS9120 is a quality management system (QMS) standard specifically designed for distributors in the aviation, space, and defense industries. Think of it as ISO 9001, plus aerospace-specific rules for things like traceability, chain of custody, handling, storage, splitting/kitting, supplier control, and documentation—all tailored to companies that procure and distribute parts rather than design or manufacture them. - AS6081

AS6081 is the anti-counterfeit standard for independent distribution and open-market procurement of electronic parts. It defines how a distributor must identify reliable sources, assess risk, verify parts (including testing), control suspect/counterfeit findings, and report incidents. The latest revision is AS6081A (April 21, 2023), which, among other updates, aligns counterfeit-detection test methods with the AS6171 family of test standards.

In short, AS9120 governs how a distributor runs a traceable, compliant quality system; AS6081 governs how an independent distributor prevents, detects, and responds to counterfeit risk in open-market sourcing.

Why these standards exist (and why they matter now)

Counterfeit or misrepresented electronics are not a theoretical problem. When they slip into aircraft avionics, life-support equipment, or critical infrastructure, the consequences are severe. AS6081 was created specifically to counter the rising tide of fraudulent parts entering high-reliability supply chains, while AS9120 harmonizes distributor quality expectations across the aerospace industry so buyers aren’t guessing whether a supplier’s practices are “good enough.”

Both are part of a broader, industry-run ecosystem led by the IAQG and published by SAE International. That ecosystem includes the AS6171 test methods used by accredited labs to detect suspect/counterfeit EEE parts and the global OASIS database, which lists certified suppliers. For you, that means fewer one-off requirements, more comparability across suppliers, and higher confidence that your partner’s certificate actually maps to robust, auditable controls.

AS9120 in practice: what buyers should expect

AS9120 translates aerospace expectations into distributor processes. Here’s what that looks like for you as a customer:

- Traceability that holds up under scrutiny

Every unit must be traceable through receipt, storage, splitting, kitting, and release. Documentation must link delivered quantities, configuration, and purchase orders, preserving the chain of custody from authorized sources or controlled external providers. - Supplier controls and risk-based thinking

The distributor must evaluate and monitor external providers, flow down requirements, and verify that providers can meet the applicable product requirements—especially important when commodities or sources change. - Preservation & handling fit for aerospace

Storage, environmental controls, ESD protection, and packaging are defined and maintained in accordance with product specifications to prevent damage or foreign object debris (FOD) and to ensure product safety throughout the distribution process. - Nonconformity control and containment

The QMS prescribes how the distributor segregates, documents, and disposition nonconforming product, and how it communicates with customers and authorities where required. - Global recognition & auditability

AS9120 certification under the IAQG scheme is globally recognized and recorded in OASIS, which many primes and tier-ones use during supplier approval. That simplifies audits and reduces the need for duplicative questionnaires.

What about AS9100?

AS9100 is for manufacturers (design/production/service). AS9120 is specifically designed for distributors—it includes ISO 9001 requirements, plus over 100 aerospace-specific controls focused on distribution. If your supplier is a distributor, AS9120 is the right fit; if they fabricate parts, AS9100 is typically expected.

AS6081A in practice: how independent distributors mitigate counterfeit risk

While AS9120 builds a compliant QMS around distribution, AS6081A zeroes in on counterfeit avoidance when parts are procured from the open market (non-authorized channels). Here are the buyer-visible elements that matter:

- Source qualification & risk assessment

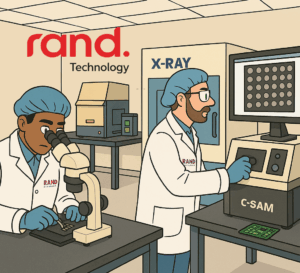

Distributors must identify reliable sources, assess part and supplier risks (including obsolescence and market conditions), and establish appropriate verification activities based on those risks. - Verification & testing aligned to AS6171

The 2023 revision eliminated older embedded test lists and points to the AS6171 test-method standard and its “slash sheets” (visual, XRF, radiography, decapsulation, electrical, and more). That means test plans are risk-based and consistent with the latest methods used by accredited labs. - Control of suspect/counterfeit parts

If parts are suspected or confirmed counterfeit, AS6081A requires segregation/quarantine, prevention of re-entry into the supply chain, and—after retention requirements—destruction or surrender to authorities. Reporting pathways are also defined. - Documentation & reporting

Detailed records of procurement, inspection/testing, and final disposition are retained. This is your audit trail: it allows your quality team to see exactly what was done, by whom, using which method, and with what results.

AS6081 vs. AS5553 vs. AS6171—what’s the difference?

- AS5553: written for OEMs/manufacturers to prevent counterfeit parts from entering builds.

- AS6081: written for independent distributors to prevent, detect, and respond to counterfeit parts in open-market sourcing.

- AS6171: the test methods standard that many labs use to perform counterfeit detection.

Working with an AS6081A-certified distributor that utilizes AS6171-aligned testing provides end-to-end coverage from sourcing through verification.

How these standards change your day-to-day

For Procurement & Sourcing

- Fewer supplier-approval headaches

An AS9120-certified distributor has already been vetted against an aerospace QMS; OASIS listings streamline your approval and surveillance. - Clear flow-downs and cleaner POs

Expect a well-structured acknowledgment of your terms (product configuration, CoC requirements, shelf life, environmental controls, RoHS/REACH, and export controls), as well as a disciplined flow-down to sub-tier test houses and couriers. - Open-market agility without blind risk

With AS6081A in place, you can leverage the open market for obsolete, long-lead, or allocation-constrained parts—with documented risk assessments and AS6171-aligned verification plans that your auditors can review.

For Quality & Compliance

- Traceability you can actually audit

Lot traceability, splitting/kitting controls, and preservation requirements decrease NCs and speed your PPAP/FAI/file reviews. - Counterfeit risk reduced and contained

If a suspect case emerges, you get swift segregation, documented analysis, and correct reporting/disposition—no mystery lots quietly re-circulating. - Alignment with lab best practices

When AS6171 test methods are used, your quality engineers are evaluating familiar artifacts (test plans, photos, radiographs, decap images, electrical data) against a common technical language.

For Engineering & Operations

- Better planning data

AS9120 emphasizes risk-based thinking and configuration management at the distributor level, improving the fidelity of lead-time, alternates, and lifecycle information you receive. - Fewer surprises at incoming inspection

Proper handling/preservation and documentation reduce MRB churn and line stoppages triggered by packaging or handling-induced issues.

“Show me” indicators: how to tell if your distributor’s program is real

Use this quick checklist when you vet distributors:

- Certificates & scope

- An up-to-date AS9120 certificate that explicitly covers distribution for the products you buy.

- An AS6081A certificate (if they source via the open market) showing independent distribution scope.

- OASIS listing that matches the legal entity on your PO.

- Test strategy & labs

- For open-market buys, ask to see risk assessments and AS6171-aligned test plans for your part types.

- Confirm the lab’s AS6171 program and ISO/IEC 17025 accreditation for the methods used (XRF, electrical, radiography, decap, etc.).

- Documentation trail

- Expect clean receiving records, photos, serial/lot data, environmental logs (where applicable), and secure CofC chains.

- Containment & reporting

- Request their written suspect/counterfeit procedure that covers segregation, notification, and final disposition per AS6081A.

- Preservation & handling

- Review their ESD controls, MSL handling, storage conditions, and packaging work instructions aligned to aerospace preservation requirements.

How Rand Technology implements (and goes beyond) the standards

At Rand, AS9120 and AS6081A aren’t badges on the wall—they’re the backbone of our operations. Here’s what that means for you:

- Aerospace-grade QMS for distribution (AS9120)

Our QMS drives traceability through receiving, storage, splitting, and kitting; codifies supplier approval and monitoring; and enforces robust preservation/handling controls. - Counterfeit avoidance built for open-market realities (AS6081A)

When obsolescence or allocation forces open-market sourcing, we apply structured risk assessment, vetted source selection, and AS6171-aligned test plans executed by accredited labs. Results (photos, data, certificates) are attached to your order’s record for complete transparency. - The Rand Certified program

Our internal 72-point inspection framework layers on top of the standards to ensure consistent incoming inspection, packaging inspection, documentation review, and visual verification—even when you aren’t specifying special requirements. ▶️ Watch the Rand Certified video for a quick explanation of how we ensure authenticity and compliance.

📄 Visit our Rand Certified Quality page to explore our certifications and detailed processes. - Audit-proven excellence

Rand has been certified to both AS9120 and AS6081 for many years, and we maintain these certifications through rigorous annual surveillance audits. In our most recent audit, Rand Technology EMEA B.V. passed with flying colors and gained an expanded scope that now includes Sales, Purchasing, Receiving, Inspection, Test, and Distribution. This outcome reflects not only compliance on paper, but also the dedication of our people in preparing for and engaging with auditors. Special recognition goes to our Netherlands Warehouse and Operations team, led by Fatima N. (Manager of QC, Test and Engineering), along with her team in QC and the Test Lab, whose effort and preparation helped demonstrate the strength of our quality system. It’s living proof that these standards are deeply embedded in Rand’s day-to-day culture. - Faster, cleaner audits

Because we operate under the IAQG scheme, your teams can confirm our certification in OASIS and reuse our artifacts (procedures, logs, and training records) during supplier audits, thereby sparing you the need for duplicate work. - Field-tested escalation

If a test lab flags an anomaly, we contain the lot, coordinate second-source testing where appropriate, and do not release product until discrepancies are resolved—with documented root cause and corrective action.

AS9120 and AS6081A together: your risk-reduction stack

Think of these standards as layers:

- AS9120 gives you confidence that the entire distribution process—from supplier approval to storage and release—operates under a disciplined, auditable QMS tailored to aerospace.

- AS6081A kicks in when you must buy outside authorized channels, ensuring sourcing rigor, verification/testing, and containment are commensurate with risk—and aligned to AS6171 test methods recognized across the industry.

Pairing both, you gain the flexibility to address real supply chain problems without compromising compliance or safety.

Common questions we hear

Is AS9120 “better” than ISO 9001?

Not exactly—it’s ISO 9001 plus aerospace-specific requirements for distributors. If you’re in the aviation, space, defense, or similarly high-reliability sectors, AS9120 is usually the expected baseline for distribution.

Do I still need AS6081 if my distributor is AS9120-certified?

If you never buy from the open market (only from direct/authorized sources), AS6081 may be less critical. However, as soon as obsolescence, allocation, or lead-time pressure forces you to use brokers or independent channels, AS6081A is what protects you—with AS6171-aligned testing to validate parts before they reach your line.

What about test standards—is AS6171 required?

AS6081A references AS6171 test methods, which many accredited labs follow to ensure consistent, risk-based detection of suspect/counterfeit EEE parts. If you’re procuring from the open market, you’ll want your distributor’s test plans to reference the relevant AS6171 methods for your device type.

Where can I verify a supplier’s certification?

The OASIS database, managed by IAQG/SAE, lists recognized aerospace-quality certifications (including AS9120). Your quality team can check the entity name, scope, and status.

Key takeaways

- AS9120 = aerospace QMS requirements for distributors (traceability, handling, supplier control, documentation).

- AS6081A = counterfeit avoidance/detection/response for independent distribution and open-market buys; aligns verification with AS6171 test methods.

- Together, they enable you to source confidently—even in constrained markets—while maintaining the auditability and safety that high-reliability products demand.

- Rand Technology doesn’t just hold these certifications—we prove them annually. Our most recent surveillance audit reaffirmed our AS9120 & AS6081 certifications and expanded our EMEA scope to cover Sales, Purchasing, Receiving, Inspection, Test, and Distribution.

Next steps

If you want to see how this looks in action:

▶️ Watch our Rand Certified video — a quick overview of how we ensure authenticity and compliance.

📄 Visit our Rand Certified Quality page — explore our certifications, inspection processes, and audit-proven standards.

With Rand Technology, you gain more than a certified distributor—you gain a partner who passes the test year after year, so you can move forward with confidence.